NEWS

Filter by Category

Filter by Tag

- Aveva

- BIM

- BIM Awards

- BVBS

- Boston Dynamics

- Bridge

- BuildingSmart

- CSi

- Cast in Place

- Concrete

- Download

- ETABS

- Education

- Extensions

- HGG

- HoloLens 2

- IDEA Statica

- IFC

- Infrastructure

- LCA

- Life Cycle Analysis

- Mixed and Augmented Reality

- Offshore

- Parametric Design

- Precast Concrete

- Quadri

- Renewable Energy

- Rhino Grasshopper

- SAP2000

- Scanning

- SitePrint

- Sitevision

- Spot

- Steel

- Sustainability

- Tekla Bridge Creator

- Tekla Modelchecker

- Tekla Structures

- Tekla Tips and Tricks

- Timber

- Tips and Tricks

- Total Station

- Training

- Trimble Connect

- Trimble Connect AR

- Trimble FieldLink

- Trimble Ri

- Trimble X9

- Webinar

- Welds

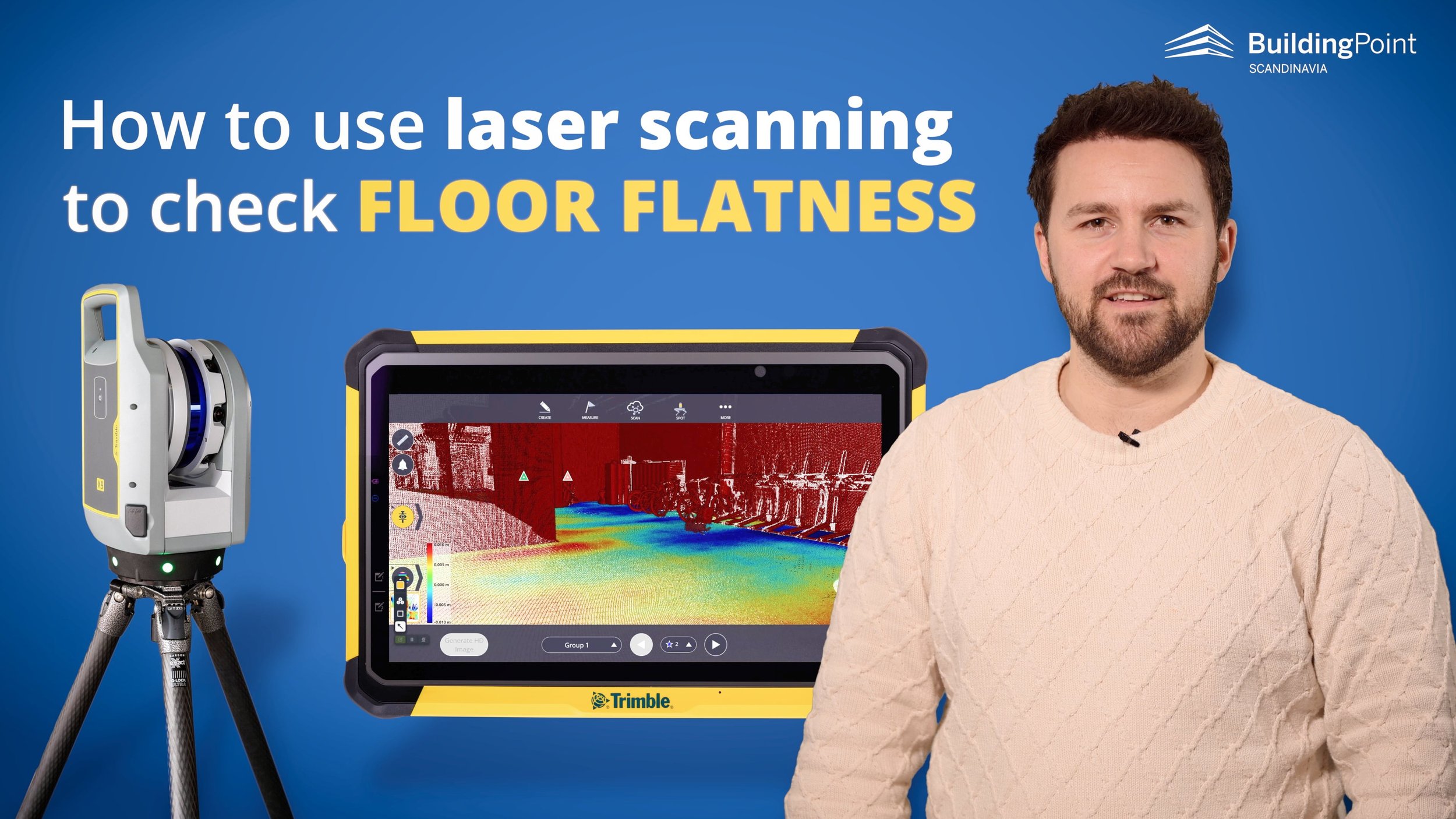

Using laser scanning to check floor flatness

Floor Flatness check using a laser scanner: To illustrate how easy it is to check and document the conditions of a floor after a pour of concrete we went to a basement to show a practical example of how laser scanning technology can be effectively used in such scenarios!

Scanner Sharing Program

Our Scanner Sharing Program is a way to get access to the benefits of scanning without a high up-front investment cost!

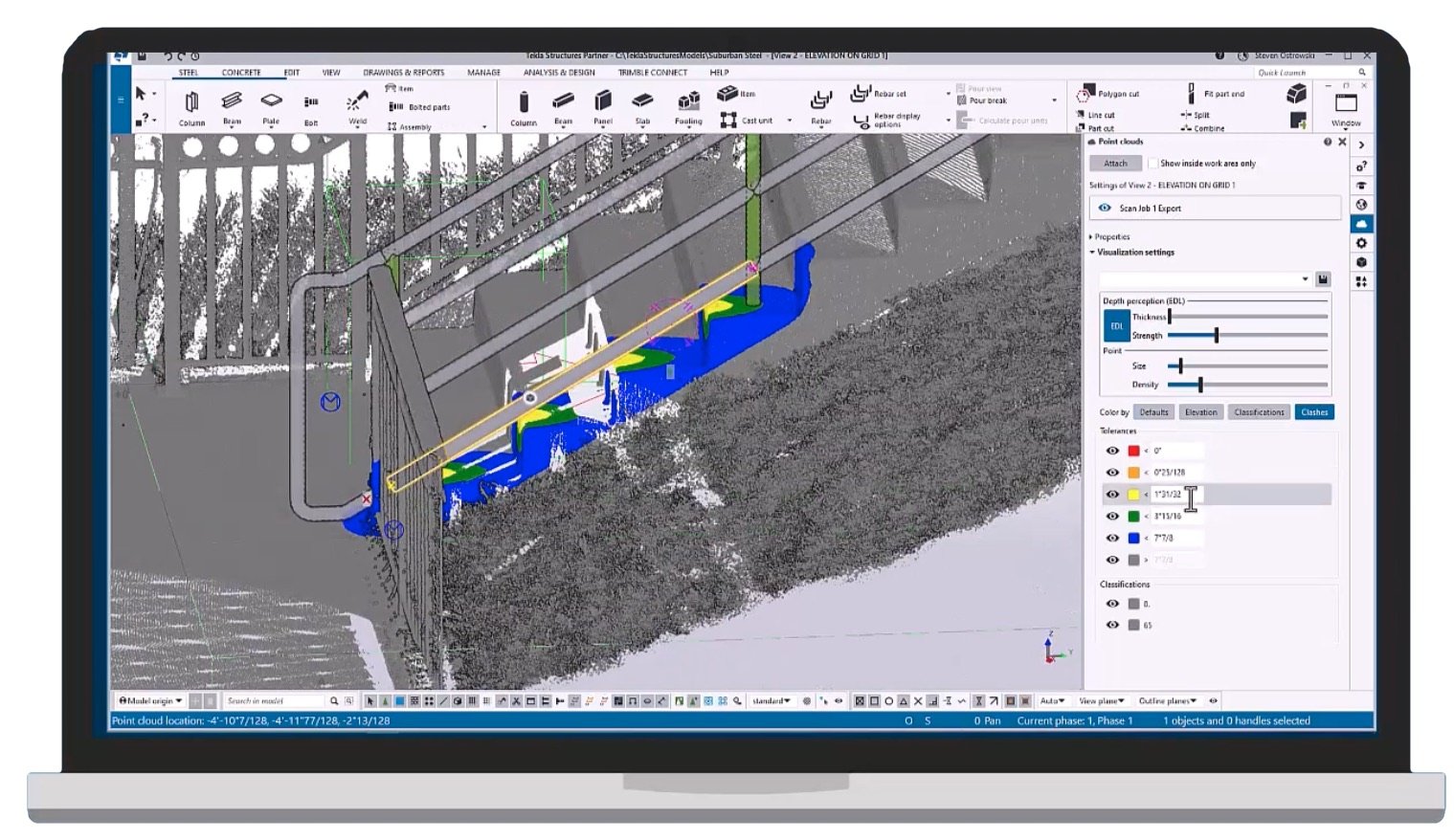

Efficient workflow with Trimble FieldLink, a Trimble scanner and Tekla: Scan to Fabrication in 20 minutes

Working smarter with scanning and BIM! This video showcases an efficient workflow for collection of scan data, on-site measurements and point cloud preparation before exporting the data to Tekla for the design of a handrail – all within a 20-minute timeframe!

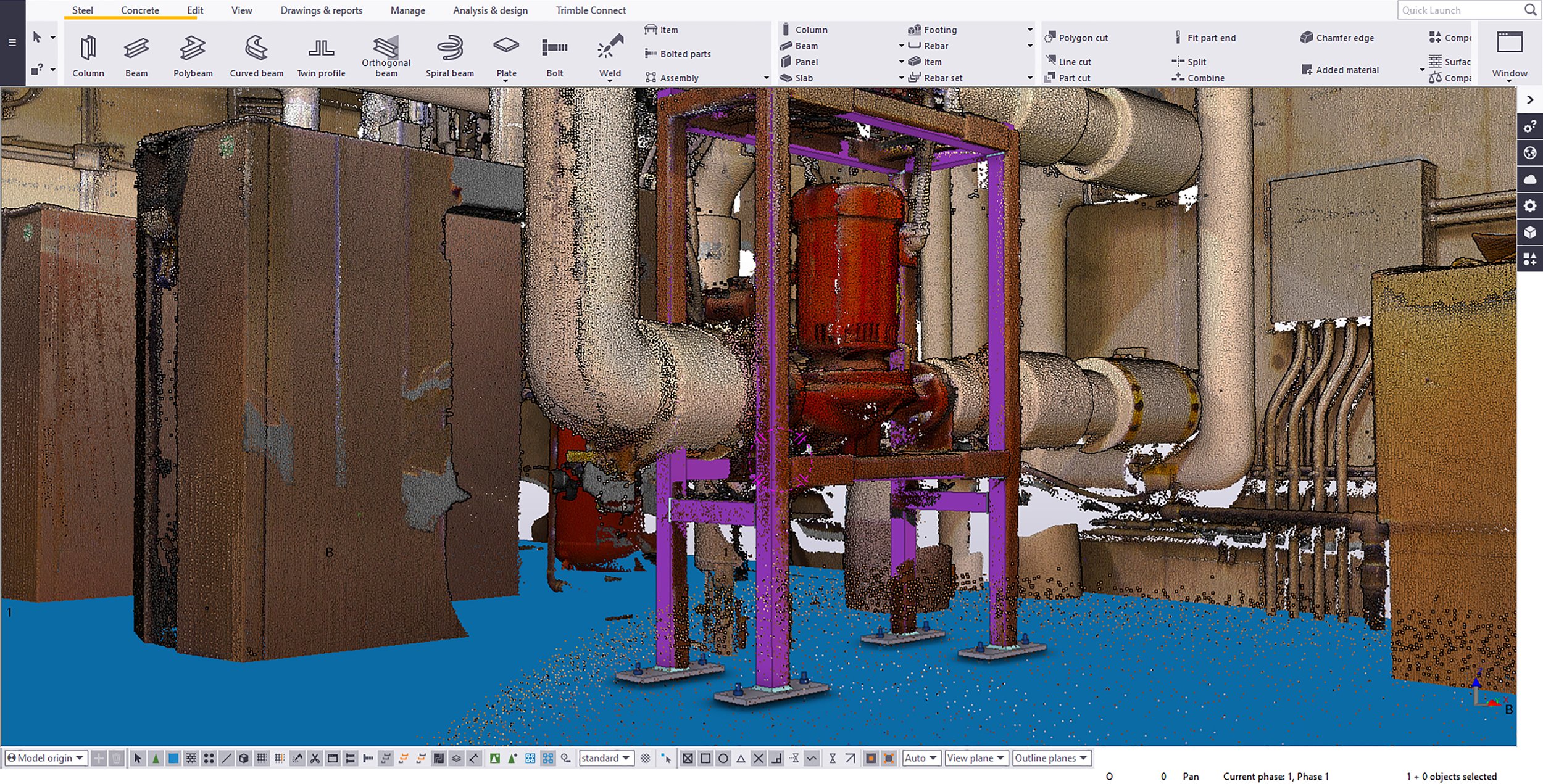

How can scanning help steel fabricators?

Steel fabricators in the Nordic were early adopters of BIM and have developed great workflows for design and fabrication over the years. Many are now looking into scanning and want to find efficient ways to consider the real world and the BIM model together for quality assurance and project planning and other benefits! In this article we will look into some use cases for scanning focused on the steel fabricator segment!

Spot Increasing Safety in Arctic Mining

As a contractor in mining and tunneling, maintaining safe operations is the no. 1 priority for LNS. However, increasing safety requirements puts business pressure on LNS, but it can also be an opportunity to innovate. Read about how Spot - the robot dog - will help LNS increase safety and productivity.

Norconsult looks to robotization to improve flow of data from the construction site

Norconsult AS and BuildingPoint Scandinavia took robot dog Spot to 4 different construction sites to see how it performs in difficult terrain, confined spaces and conditions that might be hazardous for people! Watch the video interview with Norconsult's Thomas Angeltveit to learn more!

Spot makes Tunnel Scanning safer and more efficient for Veidekke

Norway’s tunneling tradition goes back as early as 1879. However, technology has come a long way since the 19th century, and robot dog Spot is one of the most advanced and anticipated technologies to become available to improve how we do things. BuildingPoint joined Veidekke and the project team in charge of scanning and other tasks at the UDK 01 site for the Vestfoldbanen/Drammen-Kobbervikdalen – a railway tunnel project for Bane NOR to put Spot to the test!

Spot is here... but why?

The robot dog Spot generates enthusiasm and ambitious ideas about the future and now the wait is over, Spot is here! It's time to discuss what kind of value this technology can unlock (unleash!) for the Construction Industry!